The NYT has an interesting article about the increased use of 3D printers in commercial applications. Nowadays, companies are using the technology to build custom furniture, low-cost prosthetic limbs, and even housing components.

The NYT has an interesting article about the increased use of 3D printers in commercial applications. Nowadays, companies are using the technology to build custom furniture, low-cost prosthetic limbs, and even housing components.

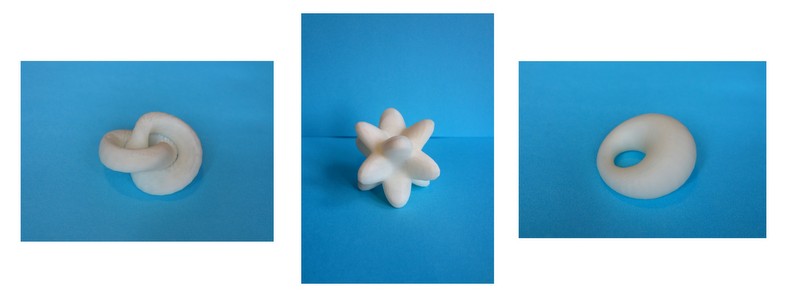

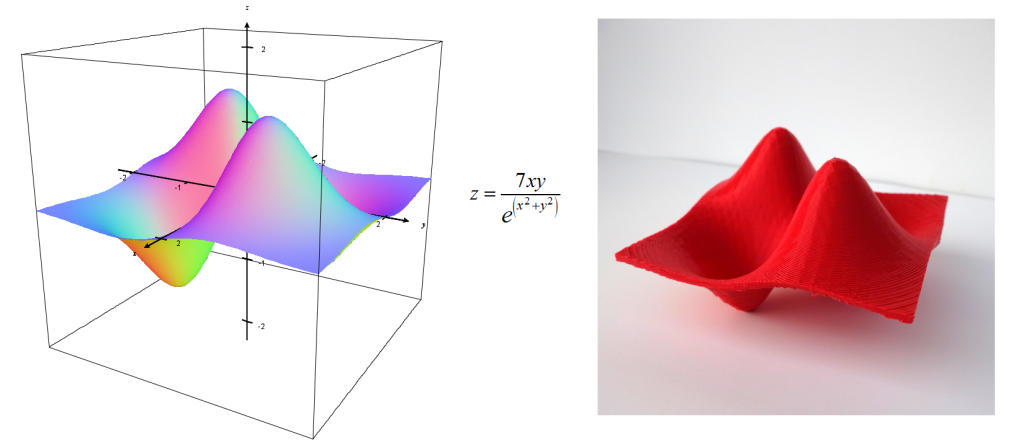

Basically, the geometry of the object is laid-out in software (like Autodesk), and the “printer” then translates the design into reality by extruding layers of hot plastic, one after another, building the object up essentially by printing one cross section at a time.

It seems that the process is becoming more commonplace and less expensive, opening the door for a wider array of commercial uses. I’ve seen students using this technology, and it is a pretty remarkable advance. I believe you can even have a custom-designed plastic guitar built!